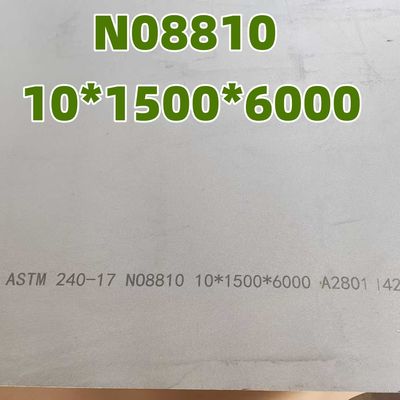

Incoloy 800H Alloys 800H (UNS N08810) Hot Rolled Nickel Alloy Plate Thickness 18mm

| Products |

Incoloy 800 / 800H Nickel Alloy Plate |

| Thickness |

0.3 - 4.0mm |

| Width |

1000mm 1219mm 1500mm or as request |

| Standard |

ASTM A240/240M-18 |

| Brand |

TISCO BAOSTEEL POSCO |

| Service |

Cutting , bending , surface finishing |

| Other Grade |

201 202 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 410 420 430 431 444,2205 2507 904L 254SMO 253MA N08020 C276 625 600 800 825 monel 400 500.etc |

| Standard Size |

1000*2000mm 1219*2438mm 1500*6000mm |

Material Description of Alloy 800/800H

Alloys 800H (UNS N08810) and 800HT (UNS N08811) are dual-certifiable Nickel-Iron-Chromium materials that resist oxidation, carburization and other high temperature corrosion. The chemical composition of the two alloys are identical to Alloy 800 (UNS N08800), with the exception of the higher level of carbon present in both grades— (0.05–0.10%) in alloy 800H, and (0.06–0.10%) in alloy 800HT. Alloy 800HT also has an addition of up 1.0 % aluminum and titanium. In addition to the chemistry restrictions, both alloys receive a high temperature annealing treatment that produces an average grain size of ASTM 5 or coarser. The restricted chemical compositions, combined with the high temperature anneal, assure these materials have greater creep and rupture strength when compared to Alloy 800.

Alloy 800H has good creep-rupture properties at temperatures above 1100°F (600°C). It remains ductile during long term use at temperatures below 1290°F (700°C) due to a maximum titanium and aluminum content of 0.7%. Alloy 800 with a standard anneal is recommended for service below 1100°F (600°C). Alloy 800H resists reducing, oxidizing and nitriding atmospheres, as well as, atmospheres that alternate between reducing and oxidizing. The alloy remains stable in long term high temperature service.

Alloy 800HT has excellent creep strength at temperatures above 1290°F (700°C). If the application involves frequent temperature excursions under 1290°F (700°C) or parts of are permanently exposed to a temperature below 1290°F (700°C), Alloy 800H should be utilized. The high temperature resistance of Alloy 800HT is comparable to Alloy 800H. It also remains stable in long term high temperature service.

Chemical Analysis of Alloy 800 / 800H

Weight % (all values are maximum unless a range is otherwise indicated)

| Element |

800H |

800HT |

| Nickel |

30.0 min.-35.0 max. |

30.0 min.-35.0 max. |

| Chromium |

19.0 min.-23.0 max. |

19.0 min.-23.0 max. |

| Iron |

39.5 |

39.5 |

| Carbon |

0.05 min.-0.10 max. |

0.06 min.-0.10 max. |

| Manganese |

1.50 |

1.50 |

| Phosphorus |

0.045 |

0.045 |

| Sulfur |

0.015 |

0.015 |

| Silicon |

1.0 |

1.0 |

| Aluminum |

0.15 min.-0.60 max. |

0.25 min.-0.60 max. |

| Titanium |

0.15 min.-0.60 max. |

0.25 min.-0.60 max. |

| Aluminum & Titanium |

0.30 min.-1.20 max. |

0.85 min.-1.20 max. |

Corrosion Resistance of 800 / 800H Alloy

The high nickel and chromium content of Alloys 800H and 800HT generally means they will have very similar aqueous corrosion resistance. The alloys have corrosion resistance that is comparable to 304 when used in nitric and organic acid service. The alloys should not be used in sulfuric acid service. They are subject to chromium carbide precipitation if in service for prolonged exposure in the 1000-1400°F (538-760°C) temperature range.

Since Alloys 800H and 800HT were developed primarily for hightemperature strength, corrosive environments to which these grades are exposed normally involve high temperature reactions such as oxidation and carburization.

Application of 800/800H alloy

- Chemical and Petrochemical Processing—process equipment for the production of ethylene, ethylene dichloride, acetic anhydride, ketene, nitric acid and oxy-alcohol

- Petroleum Refining—steam/hydrocarbon reformers and hydrodealkylation units

- Power Generation—steam super-heaters and high temperature heat exchangers in gas-cooled nuclear reactors, heat exchangers and piping systems in coal-fired power plants

- Thermal Processing Fixtures—radiant tubes, muffles, retorts and fixtures for heat-treating furnaces

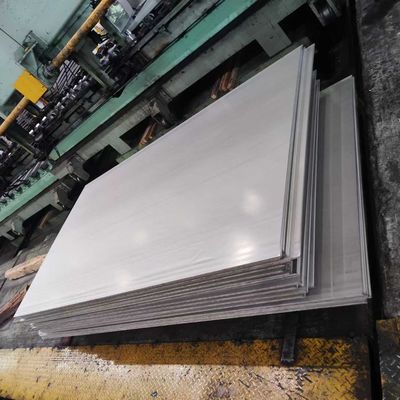

Products Show

Q: Are you a manufacturer?

A: Yes ,MITTEL is a metal manufacturer, We have own factory, which is located in JIANGSU,CHINA. We have a leading power in producing and exporting steel pipe,galvanized steel pipe,hollow section,galvanized hollow section, etc. We promise that we are what you are looking for.

Q:Can we visit your factory ?

A:Warmly welcome once we have your schedule we will pick you up .

Q: Do you have quality control?

A: Yes, we have gained BV, SGS authentication.

Q: Can you arrange the shipment?

A: Sure, we have permanent freight forwarder who can gain the best price from most ship company and offer professional service.

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 25-45 days if the goods are not in stock, it is according to quantity.

Q:How can we get the offer?

A: Please offer the specification of the product,such as material,size,shape,etc.So we can give the best offer.

Q:Can we get the some samples? Any charges?

A: Yes , we could offer the sample for free charge but do not pay the cost of freight . If you place the order after confirm the sample , we will refund your express freight or deduct it from the order amount.

Q: How do you make our business long-term and good relationship?

A: 1.We keep good quality and competitive price to ensure our customers' benefit.

2.We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q: What are terms of delivery and payment?

A: Accepted Delivery Terms: EXW,FOB,CFR,CIF,DDU,DDP

Accepted Payment Terms: T/T, L/C, D/P, etc.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!